Understanding the Refinishing Process

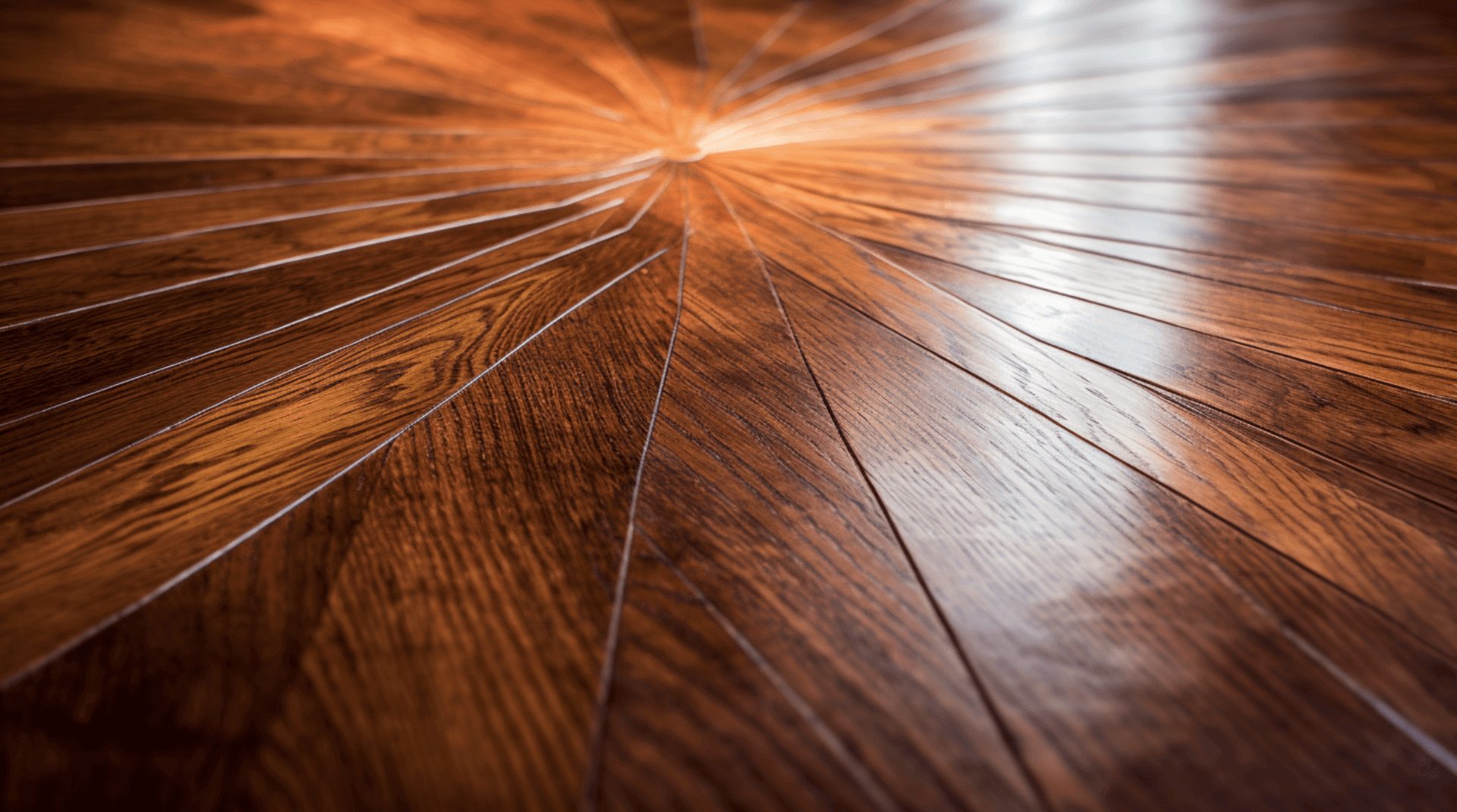

Refinishing a wooden floor is a process that involves sanding, staining, and sealing the floor to restore its original beauty and luster. This process is necessary for wooden floors because it helps to protect the wood from wear and tear, as well as from dirt and moisture. Refinishing also helps to enhance the longevity and aesthetics of wooden floors by providing a protective layer that prevents dirt and dust from settling into the wood, as well as preventing water damage.

The process of refinishing a wooden floor begins with sanding the floor to remove any existing stains, scratches, and imperfections. This is followed by staining the floor to give it a new look and feel. Finally, the floor is sealed with a protective coating to protect it from further damage.

Refinishing a wooden floor can help to enhance its longevity and aesthetics. By sanding and staining the floor, it can be restored to its original beauty and luster. The protective coating also helps to protect the floor from dirt, dust, and wear and tear. Additionally, refinishing can help to improve the overall look and feel of the floor, making it look more attractive and inviting.

Overall, refinishing a wooden floor is an important process that helps to protect the wood and enhance its longevity and aesthetics. It is beneficial for both home owners and business owners as it can improve the value of the property and create a more appealing environment.

The Importance of Timing in the Refinishing Process

Timing is crucial in the refinishing process of a wooden floor as it directly impacts the final result. Each step of the process must be carefully managed to ensure that the floor is properly prepared and the desired results are achieved.

The first step in the refinishing process is sanding the floor. This step must be done at the right time to ensure that the floor is properly prepared for staining and sealing. If the sanding is done too early, the floor may not be adequately prepared, leading to ineffective staining and sealing. Conversely, if the sanding is done too late, the floor may be damaged, compromising the overall outcome.

The second step in the refinishing process is staining the floor. Timing is crucial during this step to achieve the desired color and finish. If the staining is done too early, the color may not develop as desired, and the finish may not be optimal. On the other hand, if the staining is done too late, the color may not penetrate the wood effectively, resulting in an uneven or unsatisfactory finish.

Properly managing the timing of each step is essential to avoid potential issues. Uneven staining, poor adhesion of the sealant, and an overall unsatisfactory finish can occur if the timing is not carefully controlled. By ensuring that each step is completed at the right time, homeowners and business owners can achieve a beautifully refinished wooden floor that enhances the aesthetics and longevity of their space.

Preparing Your Wooden Floor for Refinishing

Preparing a wooden floor for refinishing is an important step in the process to ensure that the desired results are achieved. The necessary steps to prepare a wooden floor for refinishing include cleaning, repairing any damage, and sanding the floor.

The tools and materials required for the preparation process include a vacuum cleaner, a broom, a mop, a dustpan, a putty knife, a hammer, a saw, sandpaper, a pressure gauge, two steel balls, a calcium carbide reagent, safety glasses, gloves, and a dust mask. Additionally, it is important to conduct more conclusive tests to determine the water content in the dry mass of concrete, as this can affect the wood flooring to be installed.

GJP Floor Sanding can assist in the preparation process by providing professional advice and guidance. We can help to identify any potential issues and provide recommendations on the best approach to take. Additionally, we can provide the necessary tools and materials to ensure that the floor is properly prepared for refinishing. With our expertise and experience, GJP Floor Sanding can help to ensure that the preparation process is completed correctly and efficiently, resulting in a beautifully refinished wooden floor.

The Role of Drying Time in Refinishing

Drying time is an important factor in the refinishing process as it affects the overall outcome of the project. The drying time of a refinished floor typically ranges from 24 to 48 hours. this can vary depending on the type of sealant used, the temperature and humidity of the room, and the ventilation of the space.

Water-based sealants generally take longer to dry compared to oil-based sealants. Additionally, warmer and more humid environments can prolong the drying process, while cooler and drier conditions can expedite it. Proper ventilation is crucial for efficient drying as it helps remove moisture from the floor.

Considering the presence of water or condensate pipes in the sub-floor voids is important during the preparation process. If these pipes are present, they must be properly addressed to prevent any potential issues during the refinishing process.

By understanding the factors that influence drying time and taking appropriate measures, homeowners and business owners can ensure that their refinished wooden floor dries properly. This will result in a beautifully refinished floor that enhances the aesthetics and longevity of their space.

Walking on Your Refinished Floor: The Risks

Walking on a freshly refinished floor can be risky as it can damage the floor and compromise the overall outcome of the refinishing job. Walking on the floor too soon can cause the sealant to be scratched or smudged, resulting in an uneven finish. Additionally, walking on the floor before it is completely dry can cause the sealant to be smeared, resulting in an unsatisfactory finish.

To avoid damaging the refinished floor, it is important to wait for the sealant to dry completely before walking on it. The drying time of the sealant typically ranges from 24 to 48 hours, but this can vary depending on the type of sealant used, the temperature and humidity of the room, and the ventilation of the space. It is also important to consider the presence of water or condensate pipes in the sub-floor voids, as this can affect the drying time. If these pipes are present, they must be properly addressed to prevent any potential issues during the refinishing process.

Additionally, it is important to ensure that the floor meets the relevant national building regulations for thermal transmittance (U-value). This ensures that the floor provides adequate insulation and energy efficiency. To achieve this standard, it is recommended to refer to the manufacturer’s guidance for the specific sealant and flooring materials used.

By understanding the potential risks, managing the drying time, and ensuring compliance with building regulations, homeowners and business owners can protect their refinished floor and maintain its quality and longevity.

The Recommended Waiting Time Before Walking on Your Refinished Floor

Ideally, homeowners and business owners should wait for 24 to 48 hours before walking on a refinished floor. This waiting time can vary depending on the type of sealant used, the temperature and humidity of the room, and the ventilation of the space. Additionally, it is important to consider the presence of water or condensate pipes in the sub-floor voids, as this can affect the drying time. If these pipes are present, they must be properly addressed to prevent any potential issues during the refinishing process.

It is also important to ensure that the floor meets the relevant national building regulations for thermal transmittance (U-value). In England, Wales, and Northern Ireland, the floor should achieve a thermal transmittance (U-value) of at least 0.25 W/m2K, while in Scotland, the floor should achieve a thermal transmittance (U-value) of at least 0.18 W/m2K. This ensures that the floor provides adequate insulation and energy efficiency. To achieve this standard, it is recommended to refer to the manufacturer’s guidance for the specific sealant and flooring materials used.

By waiting for the recommended time and ensuring compliance with building regulations, homeowners and business owners can protect our refinished floor and maintain its quality and longevity. GJP Floor Sanding can provide professional advice and guidance to ensure optimal waiting time and compliance with regulations. We can also assist in addressing any potential issues related to water or condensate pipes, ensuring a successful refinishing process.

Protecting Your Refinished Floor PostRefinishing

Protecting a refinished floor is essential to ensure its longevity and maintain its quality. Homeowners and business owners should take steps to protect their refinished floor from dirt, dust, and other debris. Regular vacuuming and sweeping can help keep the floor clean and free from dirt and dust. Additionally, it is important to use mats and rugs to protect the floor from scratches and other damage.

Regular maintenance is also important to extend the life of a refinished floor. This includes regular cleaning and polishing, as well as addressing any signs of wear and tear, such as scratches, chips, and discoloration. If any of these signs are present, it is important to address them immediately to prevent further damage. It is also important to verify that the installation address is correct and that the technician provides their credentials to the customer. Any openings or hazards should be appropriately cordoned or barriered, and specific safety considerations recommended by the manufacturer of the product or system utilized should be followed.

Additionally, to improve the thermal performance of a suspended timber floor, homeowners and business owners can consider adding extra insulation. This can help enhance the floor’s insulation and energy efficiency. It is recommended to consult with professionals or refer to the manufacturer’s guidance for the specific insulation materials and installation techniques.

By following these steps and considering the specific needs of the refinished floor, homeowners and business owners can effectively protect and maintain their refinished floor, ensuring its longevity and preserving its quality.

Addressing Common Concerns About Refinished Floors

To address the concerns about the cost of the refinishing process, it is important to consult with professionals like GJP Floor Sanding. We can provide a detailed cost estimate based on the specific needs of the floor, taking into consideration factors such as the size of the area, the type of sealant used, and any necessary repairs. This ensures that the cost is reasonable and within the homeowner’s budget.

In terms of durability, GJP Floor Sanding uses high-quality materials and follows the manufacturer’s instructions for installation and maintenance. This ensures that the refinished floor is durable and can withstand regular wear and tear. We also take precautions to protect the floor during the refinishing process, such as ensuring no other floor traffic is allowed during sanding and finishing, and recommending the removal of furniture and old floor coverings. These measures help prevent any accidental damage and ensure a long-lasting finish.

To address the potential for damage, GJP Floor Sanding thoroughly investigates the sub-floor voids for any water or condensate pipes. This is important as it can affect the drying time and the thermal performance of the floor. By properly addressing these pipes and ensuring we do not interfere with the refinishing process, GJP Floor Sanding ensures a successful outcome.

Overall, GJP Floor Sanding understands the concerns homeowners have about refinished floors and takes the necessary steps to address them. We provide professional advice, use high-quality materials, and follow best practices to ensure that the refinished floor is durable, long-lasting, and meets the expectations of homeowners and business owners.

The Role of Professional Services in Floor Refinishing

Hiring professional services for floor refinishing, such as GJP Floor Sanding, is highly recommended to ensure a successful and satisfactory outcome. GJP Floor Sanding is a professional floor sanding and refinishing service that goes above and beyond to provide exceptional results.

We use high-quality materials and strictly adhere to the manufacturer’s instructions for installation and maintenance. This ensures that the refinished floor is of the highest quality and durability. GJP Floor Sanding takes great care in protecting the floor during the refinishing process. We ensure that no other floor traffic is allowed during sanding and finishing, recommend the removal of furniture and old floor coverings, and use dust sheets to safeguard the customer’s property.

GJP Floor Sanding conducts a thorough investigation of the sub-floor voids to identify any water or condensate pipes that may affect the drying time and thermal performance of the floor. We also verify the installation address and provide our credentials to the customer, ensuring a professional and trustworthy service. Any openings or hazards are appropriately cordoned or barriered, and we strictly follow safety considerations recommended by the manufacturer.

By hiring GJP Floor Sanding, customers can expect not only a beautifully refinished floor but also exceptional customer satisfaction. We provide ongoing support and maintenance advice to help customers maintain the quality and longevity of our refinished floor. With our expertise, attention to detail, and commitment to customer satisfaction, GJP Floor Sanding is the ideal choice for professional floor refinishing services.

GJP Floor Sanding’s Approach to Wooden Floor Refinishing

GJP Floor Sanding takes a comprehensive approach to wooden floor refinishing. We use high-quality materials and strictly adhere to the manufacturer’s instructions for installation and maintenance, ensuring that the refinished floor is of the highest quality and durability. GJP Floor Sanding takes great care in protecting the floor during the refinishing process. We ensure that no other floor traffic is allowed during sanding and finishing, recommend the removal of furniture and old floor coverings, and use dust sheets to safeguard the customer’s property.

GJP Floor Sanding conducts a thorough investigation of the sub-floor voids to identify any water or condensate pipes that may affect the drying time and thermal performance of the floor. We also verify the installation address and provide our credentials to the customer, ensuring a professional and trustworthy service. Any openings or hazards are appropriately cordoned or barriered, and we strictly follow safety considerations recommended by the manufacturer.

In addition to our meticulous approach, GJP Floor Sanding also provides valuable advice on retrofit floor insulation. We understand the importance of improving the floor’s thermal performance and energy efficiency. By offering guidance on the best insulation materials and installation techniques, GJP Floor Sanding helps homeowners and business owners enhance the overall performance of our refinished floor.

With our attention to detail, commitment to using the right materials and techniques, and additional expertise in retrofit floor insulation, GJP Floor Sanding stands out in the industry. Customers can trust us to deliver exceptional results and a beautifully refinished wooden floor that not only looks great but also provides enhanced energy efficiency and comfort.

Expert Advice from GJP Floor Sanding

GJP Floor Sanding offers expert advice on maintaining refinished floors. We provide ongoing support and maintenance advice to help customers maintain the quality and longevity of our refinished floor. This includes advice on cleaning and caring for the floor, as well as tips on how to protect it from damage.

To clean the refinished floor, GJP Floor Sanding recommends using a soft-bristled broom or vacuum cleaner to remove dirt and debris. We also suggest using a damp mop with minimal water to clean the floor, as excessive water can damage the finish. Harsh chemicals and abrasive cleaners should be avoided, as we can also harm the floor’s finish.

In terms of protection, GJP Floor Sanding advises using furniture pads or felt protectors on the legs of furniture to prevent scratches and dents. We also recommend using rugs or mats in high-traffic areas to minimize wear and tear. It is important to avoid dragging furniture across the floor, as this can cause scratches and damage the finish.

Additionally, GJP Floor Sanding provides guidance on retrofit floor insulation to improve the floor’s thermal performance and energy efficiency. We offer advice on selecting the best insulation materials and proper installation techniques. Thoroughly inspecting the foundation walls for cracks is also recommended, as this can indicate potential issues that may affect the wood subfloor and flooring.

By following the expert advice from GJP Floor Sanding, homeowners and business owners can benefit from floors that not only look great but also maintain our quality and durability over time. These tips help prolong the life of refinished floors and ensure we continue to enhance the aesthetics and value of the property.

Contact GJP Floor Sanding for Your Wooden Floor Refinishing Needs

For all your wooden floor refinishing needs, contact GJP Floor Sanding. We offer a comprehensive range of services to assist with the refinishing process, from initial assessment and preparation to installation and maintenance.

GJP Floor Sanding takes great care in protecting the floor during the refinishing process. We ensure that no other floor traffic is allowed during sanding and finishing, recommend the removal of furniture and old floor coverings, and use dust sheets to safeguard the customer’s property. We also conduct a thorough investigation of the sub-floor voids to identify any water or condensate pipes that may affect the drying time and thermal performance of the floor. We verify the presence of a damp proof course (DPC) and inspect for signs of rot or decay in the joist ends. This attention to detail ensures that the refinishing job is done with precision and addresses any potential issues that may affect the longevity and quality of the floor.

In addition to our meticulous approach, GJP Floor Sanding provides valuable advice on retrofit floor insulation. We understand the importance of improving the floor’s thermal performance and energy efficiency. By offering guidance on the best insulation materials and installation techniques, we help homeowners and business owners enhance the overall performance of our refinished floor. This additional expertise sets us apart in the industry and ensures that customers receive not only a beautifully refinished floor but also one that provides enhanced energy efficiency and comfort.

Contact GJP Floor Sanding today to discuss your wooden floor refinishing needs and benefit from our expertise and exceptional customer service.