Understanding Radiant Heating Systems and Wooden Floors

Radiant heating systems are an efficient and cost-effective way to heat a home or business. These systems work by transferring heat from a hot surface to a cooler one, such as a floor or wall. This is achieved through a series of pipes that are heated by a boiler or other heat source. The heat is then transferred to the floor or wall, which in turn radiates the heat into the room.

When it comes to wooden floors, there are certain types of wood that are compatible with radiant heating systems. Hardwood floors, such as oak, maple, and cherry, are the most common types of wood used in these systems. They are more resistant to heat and moisture, making them ideal for use with radiant heating. Softwood floors, such as pine and cedar, can also be used, but they are not as efficient and may be more prone to warping and cracking.

It is important to consider how a radiant heating system can affect a wooden floor. The heat from the system can cause the wood to expand and contract, which can lead to gaps between the boards. To prevent this, it is crucial to ensure that the floor is properly sealed and that the temperature of the system is not too high. Additionally, proper insulation is necessary to prevent heat loss and maintain the efficiency of the system.

The Feasibility of Sanding and Refinishing a Wooden Floor with a Radiant Heating System

Sanding and refinishing a wooden floor with a radiant heating system is a feasible option, but there are several considerations to keep in mind. The most important factor is the type of wood used in the floor. Hardwood floors, such as oak, maple, and cherry, are the most suitable for radiant heating systems, as they are more resistant to heat and moisture. Softwood floors, such as pine and cedar, can also be used, but they are not as efficient and may be more prone to warping and cracking.

When sanding and refinishing a wooden floor with a radiant heating system, there are potential risks that must be taken into account. The heat from the system can cause the wood to expand and contract, which can lead to gaps between the boards. Additionally, the sanding process can create dust particles that can be drawn into the heating system, leading to clogs and reduced efficiency. It is also important to inspect the water or condensate pipes in the sub-floor voids for the presence of pipes, as these will have an increased risk of freezing should the floor be insulated and the pipe left exposed to the colder void environment after the works.

To mitigate these risks, it is important to ensure that the floor is properly sealed and that the temperature of the radiant heating system is not too high. Proper insulation should be installed to prevent heat loss and maintain the efficiency of the system. During the sanding process, precautions should be taken to minimize dust and keep the heating system clean. Additionally, it is crucial to inspect and protect any water or condensate pipes in the sub-floor voids to prevent freezing.

By considering these factors and taking the necessary precautions, homeowners and business owners can successfully sand and refinish a wooden floor with a radiant heating system, enjoying the benefits of both a beautiful floor and efficient heating.

Preparing Your Wooden Floor for Sanding and Refinishing

Preparing a wooden floor with a radiant heating system for sanding and refinishing requires careful consideration and preparation. The first step is to inspect the floor for any potential hazards, such as exposed nails or other sharp objects. These should be removed or covered to prevent any potential injuries during the sanding process.

It is also important to protect the radiant heating system during the process. This can be done by ensuring that the temperature of the system is not too high and that the floor is properly sealed. Additionally, proper insulation should be installed to prevent heat loss and maintain the efficiency of the system. Cross-flow of air should be considered, as well as tassel walls (if present) to allow for air flow. Sub-floor ventilation grilles should also be inspected.

The timber floor should be suitable for use with a radiant heating system, and verification should be made that it is not located above a heated space. The construction of the ground floor, including the type of timber joists and any signs of rot or decay, should be visually inspected. The whole ground floor or the floor above unheated space should be properly insulated to ensure optimal performance.

By taking these steps and considering the additional context provided, homeowners and business owners can ensure that their wooden floor with a radiant heating system is properly prepared for sanding and refinishing, resulting in a beautiful and efficient floor.

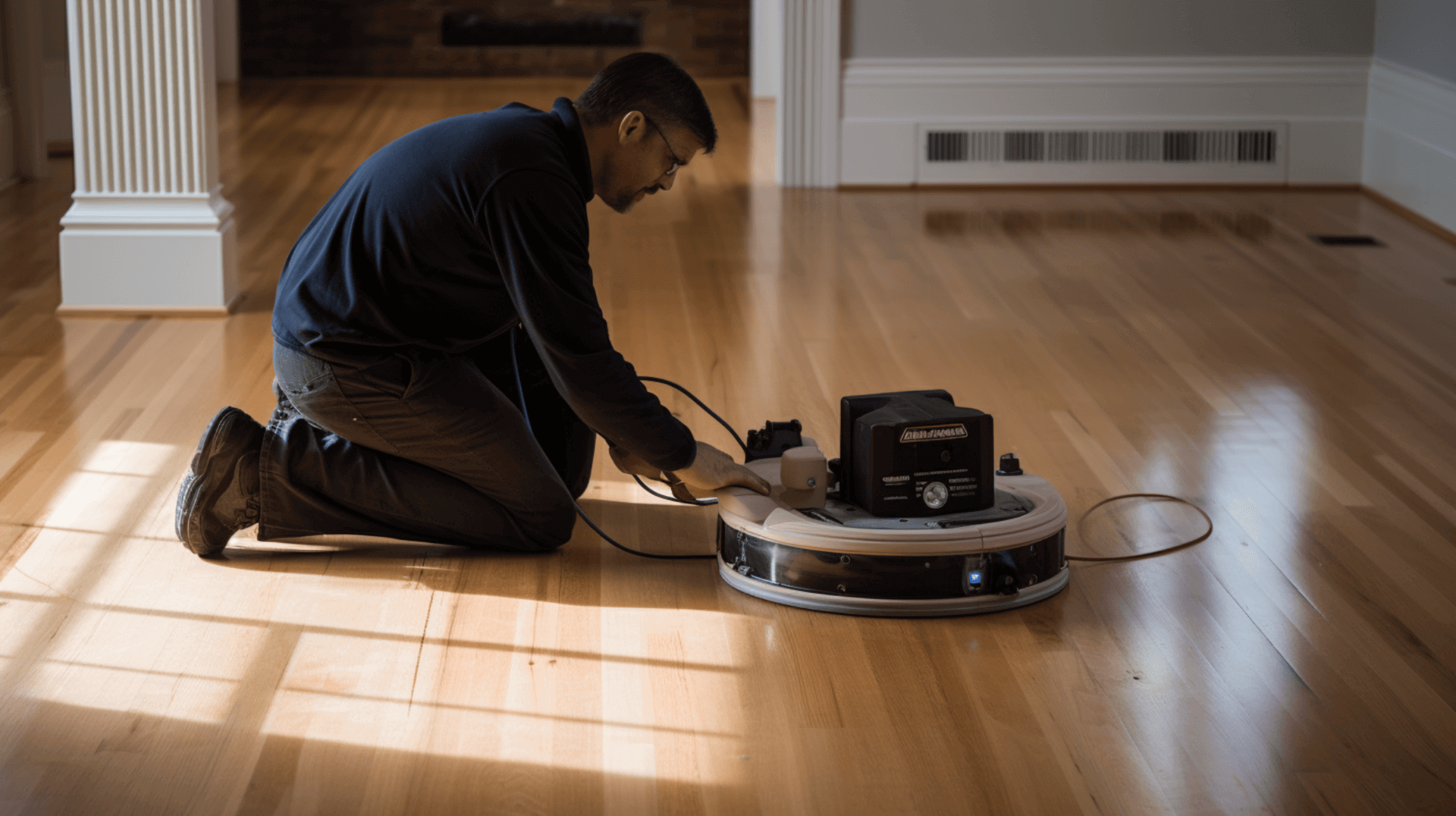

Choosing the Right Equipment for Sanding a Wooden Floor with a Radiant Heating System

When sanding a wooden floor with a radiant heating system, it is important to choose the right equipment. The most suitable types of sanders for this type of floor are drum sanders and orbital sanders. Drum sanders are powerful and efficient, making them ideal for sanding large areas. they can be challenging to control and may cause damage if not used properly.

Orbital sanders, on the other hand, are more commonly used and are better suited for smaller areas. They are easier to control and less likely to cause damage to the floor. they may take longer to cover a large area compared to drum sanders.

Regardless of the type of sander used, it is essential to take precautions to protect the radiant heating system. This includes ensuring that the temperature of the system is not too high and that the floor is properly sealed. Adequate insulation should also be installed to prevent heat loss and maintain the system’s efficiency.

To achieve the desired U-value and ensure optimal performance, there are a range of insulation materials available on the market. It is recommended to consult with a professional or the flooring manufacturer to determine the most suitable insulation material for the specific radiant heating system and wooden floor.

By selecting the appropriate sanding equipment and following the manufacturer’s guidelines, homeowners and business owners can successfully sand a wooden floor with a radiant heating system, ensuring both a beautifully sanded floor and an efficient heating system.

The Sanding Process for a Wooden Floor with a Radiant Heating System

Once the right equipment is chosen, the sanding process can begin. The floor should be sanded in a series of passes, starting with a coarse grit sandpaper and gradually working up to a finer grit. This will ensure a smooth and even finish. It is important to take precautions to protect the radiant heating system during the sanding process. This includes ensuring that the temperature of the system is not too high and that the floor is properly sealed. Adequate insulation should also be installed to prevent heat loss and maintain the system’s efficiency.

To achieve the desired smooth and even finish, it is important to follow the manufacturer’s guidelines for sanding. This may include using a specific type of sandpaper that is recommended for the type of wood and finish on the floor. Different grits of sandpaper may be needed for different stages of the sanding process. Starting with a coarse grit sandpaper will help to remove any imperfections or old finish, while gradually moving to finer grits will help to smooth out the surface.

During the sanding process, it is important to keep the sandpaper moving in a consistent and even motion. Sanding in the direction of the wood grain can help to prevent scratches and ensure a more uniform finish. It is also important to periodically check the sandpaper for wear and replace it as needed to maintain optimal sanding performance.

By following these steps and using the appropriate sanding equipment and sandpaper, homeowners and business owners can achieve a smooth and even finish on their wooden floor with a radiant heating system, resulting in a beautifully restored floor.

Refinishing Your Wooden Floor: Selecting the Right Materials

When refinishing a wooden floor with a radiant heating system, it is important to select the right materials, including the type of finish. The most suitable type of finish for this type of floor is a water-based finish. Water-based finishes are durable, easy to apply, and do not interfere with the performance of the radiant heating system. They are also low in VOCs, making them a more environmentally friendly option.

Oil-based finishes are also suitable for use with a radiant heating system, but they may require more maintenance and can potentially interfere with the system’s performance. It is important to consider the specific characteristics of the wood species and how it changes dimension with temperature fluctuations. This can be largely influenced by the categories directly related to the wood species.

Polyurethane finishes, on the other hand, are not recommended for use with a radiant heating system as they can interfere with the system’s performance and may require more frequent maintenance.

It is important to ensure that the U-value is calculated in accordance with the conventions in the current version of BR443 conventions for calculating U-values. If replacing at least one joist, it is important to inspect the timber to ensure it is suitable for use with a radiant heating system.

When selecting a finish, it is important to consider the type of wood and the desired look and feel of the floor. Different finishes provide varying levels of protection and will impact the overall appearance of the floor. It is recommended to consult with a professional or the flooring manufacturer to determine the most suitable finish for the specific radiant heating system and wooden floor.

The Refinishing Process for a Wooden Floor with a Radiant Heating System

When refinishing a wooden floor with a radiant heating system, it is important to select the right materials, including the type of finish. The most suitable type of finish for this type of floor is a water-based finish. Water-based finishes are durable, easy to apply, and do not interfere with the performance of the radiant heating system. They are also low in VOCs, making them a more environmentally friendly option.

Oil-based finishes are also suitable for use with a radiant heating system, but they may require more maintenance and can potentially interfere with the system’s performance. It is important to consider the specific characteristics of the wood species and how it changes dimension with temperature fluctuations. This can be largely influenced by the categories directly related to the wood species, such as the U-value, which should be calculated in accordance with the conventions in the current version of BR443 conventions for calculating U-values. If replacing at least one joist, it is important to inspect the timber to ensure it is suitable for use with a radiant heating system.

Polyurethane finishes, on the other hand, are not recommended for use with a radiant heating system as they can interfere with the system’s performance and may require more frequent maintenance.

To ensure a durable and attractive finish, it is important to follow the manufacturer’s instructions for the specific type of finish being used. This may include using a brush or roller to apply the finish and ensuring an even and consistent coverage. It is also important to take precautions to protect the radiant heating system during the refinishing process. This includes ensuring that the temperature of the system is not too high and that the floor is properly sealed. Adequate insulation should also be installed to prevent heat loss and maintain the system’s efficiency.

By selecting the appropriate materials, following the recommended application techniques, and taking necessary precautions, homeowners and business owners can achieve a durable and attractive finish on their wooden floor with a radiant heating system. This will result in both a beautifully refinished floor and an efficient heating system.

PostRefinishing Care for Your Wooden Floor with a Radiant Heating System

Once a wooden floor with a radiant heating system has been sanded and refinished, it is important to take the necessary steps to maintain the floor and protect the radiant heating system. This includes regularly cleaning the floor to remove dirt and debris, using a damp mop or cloth and avoiding the use of harsh chemicals or abrasive cleaners that can damage the finish and interfere with the system’s performance.

To protect the radiant heating system during the refinishing process, it is crucial to ensure that the temperature is not set too high and that the floor is properly sealed. Adequate insulation should also be installed to prevent heat loss and maintain the system’s efficiency. It is important to calculate the U-value in accordance with the conventions outlined in the current version of BR443 conventions for calculating U-values. Additionally, when replacing at least one joist, it is essential to inspect the timber to ensure its suitability for use with a radiant heating system.

By following these maintenance and protection measures, homeowners and business owners can maximize the lifespan of their refinished wooden floor with a radiant heating system while ensuring optimal performance and efficiency.

Troubleshooting Common Issues with Wooden Floors and Radiant Heating Systems

Common issues that may arise with wooden floors and radiant heating systems include uneven heating, inadequate insulation, and improper installation. Uneven heating can occur when the floor is not properly sealed or insulated, resulting in heat loss and an uneven temperature across the floor. Inadequate insulation can also lead to heat loss and an inefficient system. Improper installation can cause the system to malfunction or fail to operate correctly.

To address or prevent these issues, it is important to ensure that the floor is properly sealed and insulated, and that the U-value is calculated in accordance with the conventions in the current version of BR443 conventions for calculating U-values. Additionally, when replacing at least one joist, it is essential to inspect the timber to ensure its suitability for use with a radiant heating system. It is also important to check that the materials have been certified and meet the necessary technical approvals for specific applications. Referring to manufacturer’s specification sheets can provide valuable information on the suitability of the material for use as UFI (Underfloor Insulation). Some materials may be more suitable for insulating suspended timber floors in older buildings.

Regular maintenance and monitoring are crucial to identify and address any potential issues. Homeowners and business owners should be vigilant for signs of uneven heating, inadequate insulation, or improper installation. If any of these signs are noticed, it is important to take immediate action, such as adjusting the temperature, resealing the floor, or seeking professional assistance.

By following these measures and addressing any issues promptly, homeowners and business owners can ensure the longevity and optimal performance of their wooden floors with radiant heating systems.

Professional Services for Sanding and Refinishing Wooden Floors with Radiant Heating Systems

GJP Floor Sanding takes the necessary precautions to ensure the safety and integrity of the radiant heating system during the sanding and refinishing process. This includes carefully monitoring and controlling the temperature to prevent any damage to the floor or the heating system. The company also ensures that the floor is properly sealed and insulated to maintain the system’s efficiency and prevent heat loss. Adequate insulation is installed to provide optimal performance.

Furthermore, GJP Floor Sanding pays close attention to the materials used in the refinishing process. We ensure that these materials are certified and meet the necessary technical approvals for specific applications. This ensures that the floor not only looks beautiful but also functions optimally with the radiant heating system.

In addition to these precautions, GJP Floor Sanding believes in keeping the customer fully informed throughout the process. We provide clear communication about the work being carried out, ensuring that the customer understands the steps taken to protect the radiant heating system and maintain its integrity.

By taking these measures, GJP Floor Sanding ensures that the sanding and refinishing process is not only effective in transforming the appearance of the wooden floor but also safe and beneficial for the radiant heating system. Customers can trust in the expertise and professionalism of GJP Floor Sanding to deliver a high-quality finish while safeguarding the performance of our heating system.

Insights from GJP Floor Sanding Experts

GJP Floor Sanding experts understand the importance of properly sealing and insulating the floor to maintain the efficiency of the radiant heating system and prevent heat loss. We also recognize the significance of following a systemized approach and providing clear guidance on the safe and effective installation of insulation measures.

Under the latest iteration of the Energy Company Obligation (ECO), insulating suitable floors has become a common practice to achieve high levels of efficiency in homes. GJP Floor Sanding experts align with this approach and emphasize the need for homeowners and business owners to be aware of the requirements and guidelines set forth by ECO.

By adhering to these guidelines and implementing proper insulation measures, customers can maximize the performance and energy efficiency of our radiant heating systems. GJP Floor Sanding experts are well-versed in these practices and can provide valuable insights and assistance to ensure the best results for our customers’ wooden floors.

Contact GJP Floor Sanding for Your Wooden Floor Needs

GJP Floor Sanding experts are highly experienced and knowledgeable in the field of sanding and refinishing wooden floors with radiant heating systems. We prioritize the safety and integrity of the heating system throughout the entire process. This includes taking necessary precautions such as verifying the installation address, using shoe protectors/covers when entering the property, and following any specific safety considerations recommended by the manufacturer.

Clear communication and guidance are key aspects of GJP Floor Sanding’s approach. We ensure that customers fully understand the purpose of the visit and the steps taken to protect the radiant heating system. Additionally, we provide information on the latest national building regulations and manufacturer’s guidance to ensure compliance and optimal performance.

By choosing GJP Floor Sanding, customers can expect exceptional results, professional service, and the preservation of our radiant heating system’s performance. The company’s expertise and attention to detail make us the ideal partner for all wooden floor sanding and refinishing needs.